In the context of the growing demand for sustainable energy, Vietnam’s sawdust charcoal has emerged as an effective solution. This closed-loop production process not only optimizes the use of recycled materials and reduces production costs. Moreover, it helps minimize environmental impact.

Vietnam’s sawdust charcoal is made from by-products such as sawdust, wood scraps, and defective wood products. At the same time, it offers high utility with long-lasting burn, high calorific value, and eco-friendly characteristics.

Vietnam’s sawdust charcoal

There are multiple steps of making good quallity of Vietnam’s sawdust charcoal:

Step 1: Material grinding

The input materials, which are wood scraps, bark, or by-products, come from the wood processing industry. They are fed into specialized grinding machines. Here, workers crush these materials into fine particles with uniform size. Proper material size ensures that the subsequent pressing and carbonization processes proceed smoothly and achieve high efficiency.

Step 2: Drying the materials

After grinding, the sawdust still contains a certain amount of moisture. Therefore, workers should dry it reduce the moisture to a standard level, typically below 15%.

Sawdust charcoal materials

Workers use industrial rotary drum dryers to carry out the drying process. This method removes excess moisture without compromising the essential properties of the material. This stage is crucial because if the moisture content is too high, the material will be difficult to compress into molds. Consequently, the quality of the sawdust briquette charcoal after carbonization will not meet standards.

Step 3: Compressing the materials into molds

After drying, the materials are transferred to a press. The press uses high pressure to compress the sawdust into uniform briquette charcoal blocks. Typically, these blocks take the form of long sticks or small pellets.

The compression process ensures that the material binds tightly, eliminating all internal gaps, which increases density and guarantees long-burning charcoal. The pressed products have high mechanical strength and are less prone to breaking during transportation and storage.

Vietnam’s sawdust charcoal burning

Step 4: Carbonization process

The pressed blocks are then placed into a carbonization furnace. Carbonization occurs in an oxygen-limited environment at high temperatures, typically ranging from 400–700°C.

Workers should monitor this process to ensure proper temperature and duration. In this way, workers will remove all moisture and volatile compounds in the wood, leaving only pure carbon with high burning efficiency. Modern carbonization furnaces and automatic controllers will optimize temperature and timing while minimizing emissions to the environment.

Step 5: Cooling and packaging

After carbonization is complete, the charcoal is cooled naturally or using a circulating cooling system. This stage helps stabilize the structure of the charcoal, reducing the risk of cracking, breakage, or smoldering.

Then workers pack the charcoal in specialized materials, usually plastic bags or kraft paper sacks for preservation. The products undergo a final quality inspection before being shipping and distributing to the market.

Vietnam’s sawdust charcoal: Grade A

Vietnam’s sawdust charcoal has many applications:

Fuel for industrial boilers: Vietnam’s sawdust charcoal is fuel for industrial bilers of factories and enterprises. With high calorific value, long-lasting burn, and stable performance, sawdust charcoal helps businesses significantly reduce fuel costs.

Household cooking and heating: Sawdust charcoal is a popular choice for households and restaurants. This is due to its long burn time, stable heat, and low smoke emission. Compared to coal, Vietnamese sawdust charcoal is more environmentally friendly and safer for human health.

International export: With the global trend toward sustainable energy solutions, sawdust charcoal exports have become a highly sought-after product in international markets. Developed countries such as Japan, South Korea, and those in Europe have a strong demand for Vietnamese sawdust briquette charcoal.

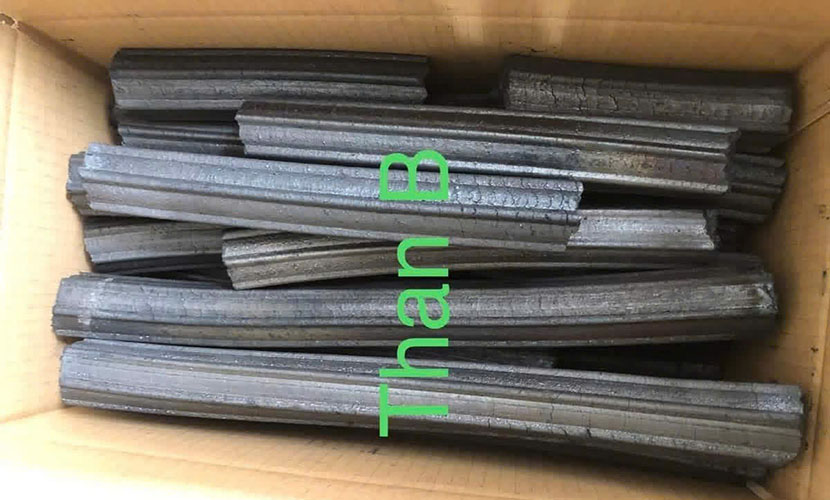

Vietnam’s sawdust charcoal: Grade B

Economic and environmental benefits of Vietnam’s sawdust charcoal

Maximizing the use of wood waste: Instead of discarding by-products from wood processing such as sawdust, wood shavings, or bark, businesses can recycle them. In this way, Vietnamese businesses of sawdust charcoal serve as raw materials for high-quality charcoal production. This approach reduces waste, conserves resources, and generates economic value from materials that would otherwise be useless.

Reducing environmental pollution: Sawdust charcoal is produced from recycled raw materials through a closed-loop process. As a result, it significantly lowers emissions and dust compared to traditional coal. Using this type of fuel in industry and households helps reduce reliance on fossil fuels, contributing to lower CO2 emissions.

Fuel cost savings: Compared to other fuels, sawdust charcoal is more cost-effective due to the utilization of readily available raw materials. Vietnam’s sawdust charcoal has long-burning characteristics and high heat output. Additionally, it helps businesses save on operational costs and optimize energy efficiency.

Export opportunities and market expansion: Vietnamese sawdust charcoal exports enjoy strong demand in international markets such as Japan, South Korea, and Europe. These countries are increasingly adopting biomass fuels to replace traditional energy sources. Therefore, significant opportunities create for Vietnamese businesses to export and enhance their brand value.

Vietnam’s sawdust charcoal: Grade C

The demand for Vietnam’s sawdust charcoal is growing rapidly, both domestically and internationally. Government policies supporting clean energy production open up numerous opportunities for sustainable investment and development.

Vietnam has a strong wood processing industry, generating a large volume of sawdust and wood waste annually. Instead of treating these materials as waste, they can effectively utilize in the sawdust charcoal forms.

Vietnamese source: https://maynghiengo.com/day-chuyen-san-xuat-than-cui-mun-cua.html