Vietnamese sawdust charcoal has another name as sawdust briquette charcoal. It is a type of sawdust biofuel, a byproduct of the wood processing industry. After compression the sawdust experiences a carbonization process in a high-temperature environment without oxygen, transforming it into charcoal. This charcoal burns for a long time and generates high heat. These characteristics make it an excellent alternative to traditional fuels such as coal and firewood.

Vietnamese sawdust charcoal is becoming an optimal choice thanks to the following outstanding features:

Smokeless and low ash: Keeps the space clean, does not pollute the air, and protects users’ health.

Long burning time and high heat output: Burns for an extended period while providing stable and strong heat.

Environmentally friendly: Made from wood waste, helping to reduce waste and conserve natural resources.

Cost-effective: Cheaper than coal and other traditional fuels.

Safe and convenient: Odorless, making it suitable for households, restaurants, and especially BBQ establishments.

Vietnamese sawdust charcoal features

In addition to sawdust briquette charcoal, coconut shell charcoal and sawdust briquette firewood are also common biofuels. There are different features among them:

Coconut shell charcoal has materials as coconut shells, a waste byproduct of the coconut industry. It burns for a very long time with high heat output. In addition, it is smokeless, low ash, and environmentally friendly. All features make it suitable for BBQ grilling or industrial use.

Coconut shell charcoal

Sawdust briquette firewood has materials from sawdust, a byproduct of the wood processing industry. It comes in stick form, with long and stable burning capability. Also, it has lower heat output compared to charcoal, making it suitable for daily cooking or boiler use. Additionally, it produces more smoke than sawdust charcoal or coconut shell charcoal. It has applications in industrial furnaces, household heaters, or cooking fuel.

Sawdust briquette firewood

Sawdust briquette charcoal is produced from sawdust that is compressed and carbonized at high temperatures in an oxygen-free environment. It has high heat output, smokeless, and low ash. It offers long burning time and excellent heat retention. Sawdust briquette charcoal does not use harmful chemicals in the production process. Therefore, it has wide applications in restaurants, BBQ establishments, and industrial furnaces.

Sawdust briquette charcoal

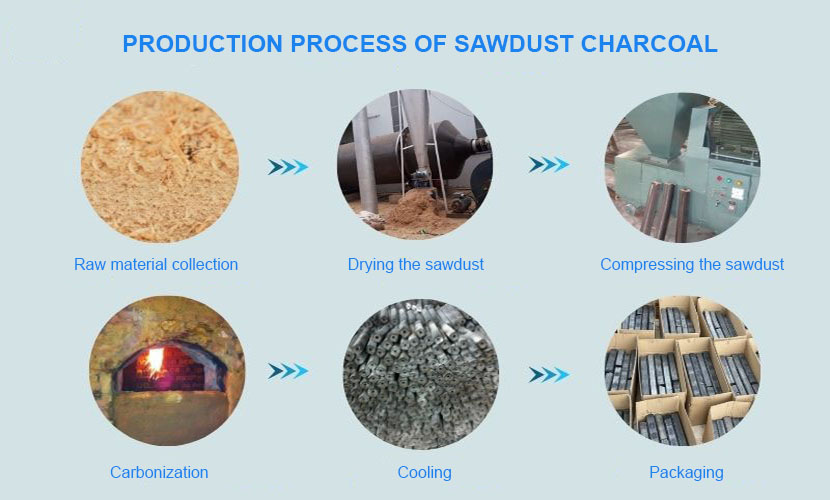

The production process of sawdust charcoal requires precision and techniques to ensure a high-quality final product. The main stages of the process include:

Raw material collection

Sawdust from wood processing factories is collected and cleaned to remove impurities.

Drying the sawdust

The sawdust makes drying process to reduce moisture content, which is essential for effective compression and combustion.

Compressing the sawdust

The sawdust experience a compression into blocks or briquettes under high pressure, forming a natural bond without the need for chemical additives.

Carbonization in an oxygen-free environment

The compressed briquettes are placed in a kiln and carbonized at high temperatures in an oxygen-free (anaerobic) environment, turning the sawdust into charcoal.

Cooling

After carbonization, the charcoal is slowly cooled to prevent cracking or structural deformation.

Packaging

Once cooled, the sawdust charcoal is packaged according to standard size, weight, and quality specifications before being distributed to the market.

Production process of sawdust charcoal

The export price of sawdust charcoal varies depending on product quality, target markets, and the specific requirements of each country. Supply sources, production costs, and global demand for biofuels also influence pricing.

Charcoal quality: Charcoal with high calorific value, low ash content, and smokeless combustion commands higher prices. Other quality indicators such as moisture content and compression density also significantly affect pricing.

Charcoal size and shape: Sawdust charcoal can be the form of pellets or blocks, each with different price points. Charcoal pellets typically fetch higher prices due to stricter technical requirements during production.

Export markets: Major markets such as Japan, South Korea, and Europe often demand higher quality charcoal, resulting in higher export prices to these regions.

Transportation costs: International shipping, especially by sea, plays a crucial role in determining the final export price of sawdust charcoal.

Currently, the export price of Vietnamese sawdust charcoal fluctuates around $500 per ton, depending on the factors mentioned above. This is a competitive price in comparison with traditional fuels, contributing to the growing appeal of sawdust charcoal in the global market.

Vietnamese sawdust charcoal has many applications in daily use:

Restaurants: Popular in BBQ restaurants due to its long-lasting heat and low smoke output.

Industry: Used as fuel for boilers and brick kilns.

Households: Used for cooking and heating during winter, especially in rural areas.

Applications of sawdust charcoal

We hope the information above has helped you better understand sawdust charcoal and its practical applications. If you need more details or wish to purchase high-quality sawdust charcoal from Vietnam, please contact Agrideco Vietnam Co., Ltd for the best consultation and support.

Vietnamese source: https://moitruongeco.vn/than-mun-cua/