In the first six months of 2025, Vietnam’s wood pellet exports reached over 3.9 million tons. Accordingly, the value was worth at $564.77 million. These figures showed an increase of 33.3% in volume and 38.8% in value compared to the same period in 2024.

However, behind these impressive figures, the wood pellet industry is facing significant challenges. Particularly, it will face with long-term sustainability and development potential.

Vietnam’s wood pellet

Japan and South Korea continue to be primary export markets for Vietnam’s wood pellet. In 2024, Japan accounted for 60% of export volume and 65% of export value. In the meanwhile, South Korea contributed 34% by volume and 28% by value.

The average export prices stood at $144.3/ton for Japan and $109.2/ton for South Korea. Notably, since September 2024, Vietnamese wood pellet prices to South Korea have risen significantly due to better auction prices and shortages of materials. It has indicated the sustainable demand in the market despite rising competition.

Reliance on these two markets offers advantages in terms of geographic proximity and preferential biomass energy policies. However, it also poses risks if demand shifts with global energy policies or market trends.

In the first half of 2025, Vietnam’s wood pellet industry experienced a double-digit growth in value. As a result, it shows the pellet sector is capitalizing on global renewable energy demand, especially amid emissions reduction efforts.

Vietnam’s wood chips

Dr. Phuc, a policy analyst at Forest Trends, notes that Vietnamese wood pellet exports reach $1 billion annually. However, the pellet industry still faces critical barriers, according to this expert.

The first barrier is the dependence on wood materials from other wood-processing sectors. This causes vulnerability to seasonal supply fluctuations, scrap price volatility, and raw material instability, especially with rising demand from Japan.

The Vietnam’s wood pellet quality is the second barrier. While companies have worked to reduce impurities, residues of chemicals and metals remain a major concern, directly related to feedstock quality. An sector’s expert points out that removing bark can meet quality standards, especially for Japanese market. However, it greatly increases production costs, far exceeding the current market price ($144/ton), making it hard for businesses to stay afloat.

Stricter requirements on sustainability and quality from export markets are the third barrier. Notably, South Korea has recently tightened its pellet standards, driving up export prices. Meanwhile, Japan required FSC/PEFC certification and is gradually implementing SBP (Sustainable Biomass Program) low-emissions chain of custody. In the future, Japan may require rigorous traceability, an area where many Vietnamese firms of wood pallets are not yet prepared.

Next, overreliance on two biggest export markets, Japan and South Korea poses a substantial risk. These two markets account for more than 95% of both export volume and value. Any policy change or increased competition could leave Vietnam’s wood pellet industry in a vulnerable position.

Finally, there is lack of linkage among exporting businesses of Vietnamese wood pellets. Specifically, the sector is polarized. Large exporters control 70% of output, while smaller producers compete fiercely for feedstock and customers.

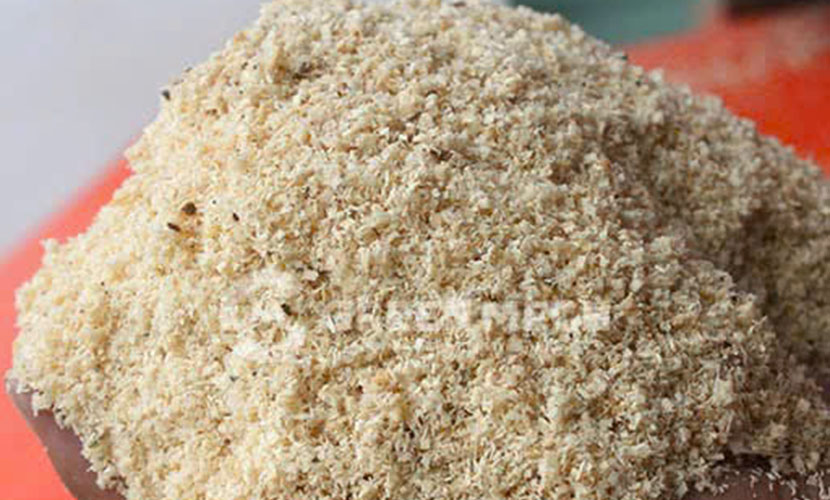

Vietnam’s wood pellet materials

Dumping in South Korea drove pellet prices below production cost in 2023, causing losses and unhealthy competition. This not only damages the industry’s reputation but also erodes the value of Vietnamese pellets compared to regional rivals.

Vietnam’s wood pellet industry not only faces internal challenges but is also under increasing pressure from emerging competitors such as Thailand, Indonesia, and Malaysia. These countries offer higher-quality pellets at more competitive prices. As a result, the elements will threaten Vietnam’s position in key markets like Japan and South Korea.

In the short term, long-term contracts help Vietnamese enterprises maintain stability. However, in the long run, if quality and sustainability standards are not improved, the industry risks losing its competitive edge.

The issue of price dumping, especially in the South Korean market, has damaged the reputation of Vietnam’s pellet industry. In 2023, export prices fell below production costs, pushing many businesses into financial hardship. It would lead to set a precedent for unhealthy competition. This not only tarnishes the country’s image but also lowers the perceived value of Vietnamese pellets compared to regional rivals.

Vietnam’s wood pellet jumbo bags

Mr. Bao, an expert, observed that the forestry sector is currently prioritizing the development of deeply processed, high value-added forest products. These include furniture, laminated wood panels, plywood, chipboard, MDF panels, wood pellets, and wood chips.

In 2024, Vietnam and Japan signed a Forestry Cooperation Agreement between Vietnam’s Department of Forestry (now the Department of Forestry and Forest Protection) and Japan’s Forestry Agency. The agreement includes cooperation on sustainable forest management, securing legal wood materials, and ensuring legal timber trade. Accordingly, raw materials used in pellet production must come from legal sources in compliance with national regulations.

Dr. Phuc recommends that businesses invest in establishing their own raw material zones. As a result, it will reduce reliance on secondary sources and to meet legal and sustainability requirements. Some pioneering companies have started applying household-group forest certifications to access more demanding markets.

However, the high cost of certification requires stable demand and price guarantees. A cooperative ecosystem in which multiple businesses share sustainable raw materials for different product lines could be a viable approach.

At the macro level, it is necessary to set up a supportive policies that will support Vietnamese wood pellet companies. They are strategic plans for the pellet industry within the broader wood ecosystem, incentives for biomass energy, and mechanisms to control unfair competition. Such measures would foster a more sustainable development environment, enabling Vietnamese businesses to compete more effectively.

Moreover, improving product quality, building strong branding, and diversifying export markets beyond Japan and South Korea, are strategic steps to affirm the position of Vietnam’s wood pellet industry.

Vietnamese source: https://baochinhphu.vn/vien-nen-go-chuan-hoa-san-xuat-de-dap-ung-nhu-cau-thi-truong-102250711140753036.htm